Electrical Considerations for Manufacturing Facilities

Manufacturing facilities are complex environments where precision, efficiency and safety are essential. Behind the scenes, electrical systems do much more than simply power equipment — they support sophisticated machinery, automation processes and high-capacity energy demands. Every connection, circuit and control unit must work seamlessly to ensure smooth production, reduce downtime, and protect personnel and equipment. In this blog, we’ll explore the most critical electrical considerations manufacturing businesses must address and the role a trusted industrial

electrician in Wollongong plays in ensuring optimal performance.

Understanding the Unique Electrical Needs of Manufacturing Facilities

Unlike commercial buildings or small workshops, manufacturing plants operate on a much larger scale. The electrical systems in these facilities must accommodate a wide range of machinery, varying voltage levels and extensive safety requirements. Poorly designed or maintained systems can quickly result in costly downtime, production errors or even safety hazards.

An industrial electrician is essential in designing, installing and maintaining the complex electrical infrastructure required in these settings. Their expertise ensures that all systems meet operational demands while remaining energy-efficient, compliant with Australian standards, and adaptable to future growth.

- Heavy machinery requires stable, high-capacity power supplies.

- Sensitive equipment needs clean, consistent voltage to prevent faults.

- Safety systems must be integrated into every part of the electrical network.

- Compliance with strict workplace regulations is mandatory for continued operation.

The Role of Motor Control Centres in Manufacturing

Motor Control Centres (MCCs) are crucial components in manufacturing electrical systems. They allow for centralised control of multiple motors, which drive conveyor belts, mixers, compressors, and other essential equipment.

Industrial electricians design MCCs to match a facility’s exact operational requirements. When built and maintained correctly, MCCs increase system reliability, make maintenance easier, and help prevent unplanned breakdowns.

- Centralised access simplifies diagnostics and repairs.

- Built-in overload protection safeguards motors against electrical faults.

- Modular design allows easy expansion as production grows.

- MCCs streamline the management of multiple motor-driven processes.

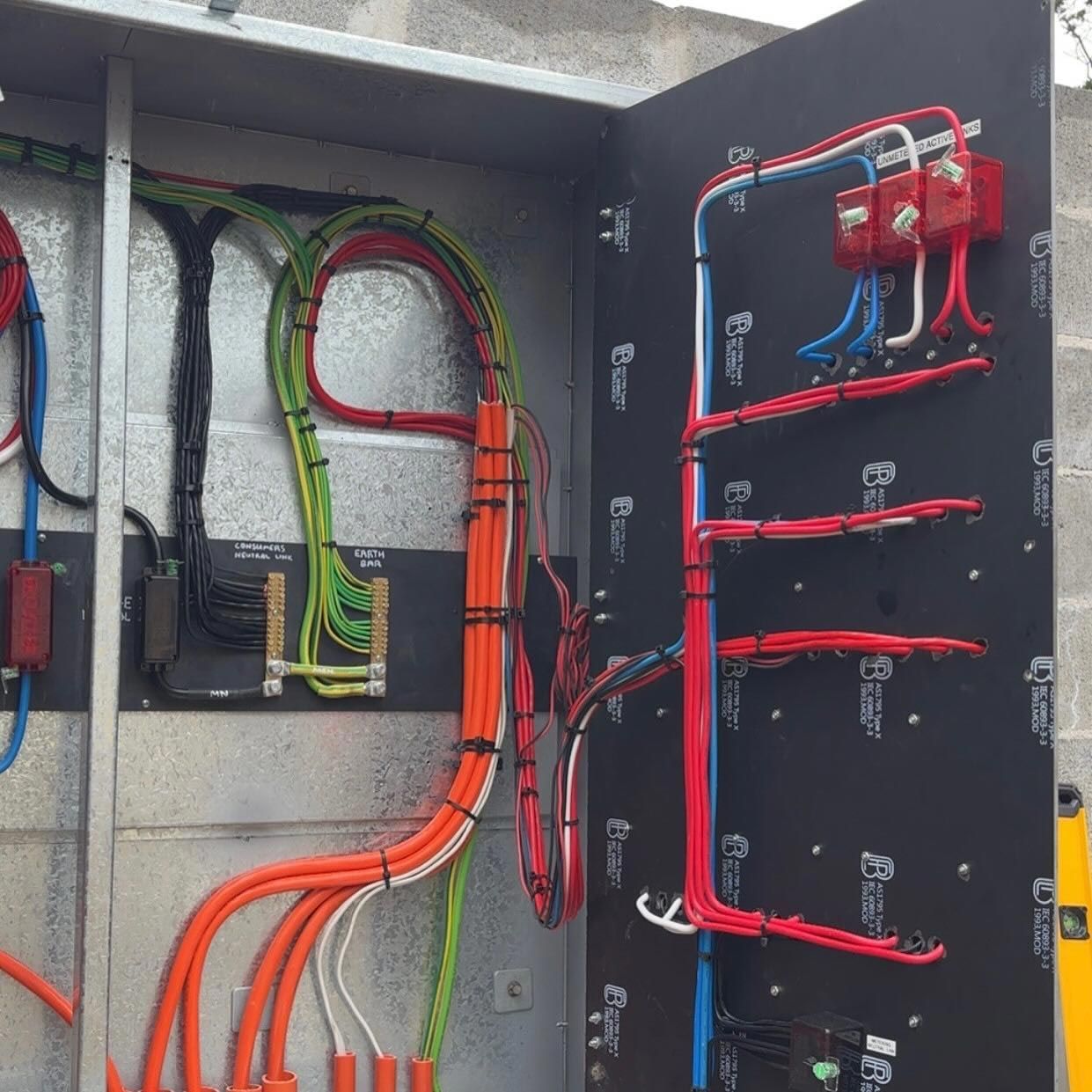

Power Distribution Systems: The Backbone of Production

Manufacturing operations often rely on large amounts of electrical power delivered consistently and safely across the facility. The power distribution system is the backbone that delivers electricity from the main supply to individual machines and systems.

Industrial electricians ensure carefully balanced power distribution to prevent overloading, reduce equipment wear, and maintain safety standards. They also design systems with scalability, allowing for seamless facility upgrades as production needs increase.

- Load balancing prevents equipment failures caused by uneven power supply.

- Redundant systems maintain power during faults or maintenance.

- Voltage regulation protects sensitive equipment from power fluctuations.

- Scalable distribution networks support facility growth without major rework.

The Importance of Automation in Modern Manufacturing

Automation is central to modern manufacturing, improving productivity, precision, and consistency. However, it also introduces new electrical complexities that must be expertly managed.

An industrial electrician’s role extends to installing, programming and maintaining advanced automation systems. This includes integrating programmable logic controllers (PLCs), robotics, and various sensors that control each stage of production.

- PLC programming ensures machines follow correct sequences and safety protocols.

- Sensors feed real-time data for quality control and system monitoring.

- Automation reduces manual intervention, increasing overall efficiency.

- Integrated safety systems prevent accidents during automated processes.

Managing High Voltage Installations Safely

Many manufacturing plants operate equipment that runs on high voltage. These systems require specialist knowledge and strict compliance with safety regulations to prevent potentially serious accidents.

Only licensed and trained industrial electricians are qualified to work on high-voltage systems. Their expertise ensures installations are completed safely, inspected regularly, and maintained to meet Australian codes and standards.

- High-voltage installations require detailed risk assessments.

- Routine inspections identify faults before they escalate into safety hazards.

- Protective equipment and safety controls minimise risk to personnel.

- Proper training ensures workers understand the dangers of high-voltage environments.

Preventive Maintenance to Reduce Downtime

For manufacturing facilities, unplanned downtime can lead to significant financial losses and production backlogs. Preventative electrical maintenance is essential to keep systems running reliably.

Industrial electricians develop customised maintenance programs tailored to each facility’s equipment, operating schedule and specific risks. Addressing small issues early helps prevent major faults that could halt production.

- Regular inspections detect worn components and wiring degradation.

- Thermal imaging identifies overheating electrical parts.

- Testing safety devices ensures proper operation during emergencies.

- Maintenance schedules can be planned around production to minimise disruption.

Upgrading Electrical Infrastructure for Expansion

As businesses grow and technology advances, many facilities require electrical upgrades to accommodate new machinery or increased production demands. Upgrades can strain existing systems without careful planning or lead to compliance issues.

Industrial electricians assess the existing infrastructure and recommend upgrades that integrate seamlessly with current systems while preparing for future requirements.

- Upgrades may involve increasing power capacity or adding new circuits.

- Automation and control systems are expanded to cover new processes.

- Energy efficiency is improved with modern equipment and smart systems.

- Compliance with updated safety codes is ensured during every upgrade.

Energy Efficiency & Sustainable Practices

Rising energy costs and growing environmental responsibilities motivate many manufacturing facilities to prioritise energy efficiency. In high-demand industrial environments, electrical systems often account for a significant portion of total operating expenses. By optimising these systems, facilities can significantly reduce energy consumption while maintaining or even improving production output.

Industrial electricians play a key role in identifying efficiency opportunities. Through detailed assessments of energy usage patterns, equipment performance, and operational processes, they design and implement tailored solutions to minimise waste and improve long-term sustainability.

- Power factor correction reduces unnecessary energy consumption.

- LED lighting retrofits lower power usage in large factory spaces.

- Variable speed drives optimise motor energy use based on load demands.

- Real-time energy monitoring helps managers make informed decisions.

Book a Consultation with Our Trusted Industrial Electricians in Wollongong

At John McEwan Electrical, we understand the electrical requirements of manufacturing facilities. As your trusted industrial electrician in Wollongong, we offer tailored services that ensure your operations remain safe, efficient, and scalable. Whether you need lighting installations or an

emergency electrician, we have the expertise to handle everything ourselves. Our team is ready to help optimise your facility’s electrical systems.

Get in touch to schedule a consultation.